Suggestions for Reducing Detergent/Lipid Emulsions:

- Apr 22, 2013

Free shipping on online orders over $1400 (contiguous US only).

Keep Soapy flows from Contacting Downstream Fats and Oils (Lipids)

Keep Soapy flows from Contacting Downstream Fats and Oils (Lipids) Better Practices in the Modern Era

Better Practices in the Modern EraWe are thankful to live in the 21st century and to not worry about dying from a restaurant dining experience. I once worked with a man whose 20 year-old brother died in 1940 of food poisoning from a restaurant with poor sanitation. As recently as the late 1940s, hot water heaters were not reliable and ware-washing detergents were caustic based. If the water was not hot, the detergent was not effective. Today’s modern restaurant has plenty of hot water, highly efficient detergents and those detergents also contain sanitizers and water softening agents to ensure complete sanitation and cleaning takes place.

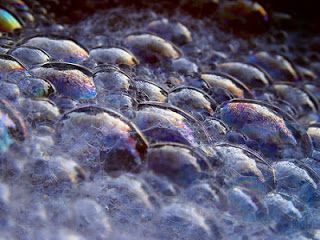

Today we have better sanitation practices and the plates are always clean, but how about what is being sent down the drain? Does it pose a problem for the community’s sewer collection system? Can the constituents be treated at the community’s wastewater treatment plant?

© 2020 Thermaco Inc. All Rights Reserved / Privacy Policy

© 2020 Thermaco Inc. All Rights Reserved / Privacy Policy