THIS COLUMN COULD SAVE YOUR LIFE

Danger Worsened by Pandemic Shutdowns

Grease interceptors are breeding grounds for deadly hydrogen sulfide gas. Dormant grease interceptors significantly elevate the danger risk. Here are the details.

Long periods of inactivity hurt seals, fuel systems, and moving parts of most mechanical systems. That’s why many automobiles don’t like it. Gas-powered lawn mowers and string trimmers don’t like it. Grease separators don’t like it either.

The inactivity caused by pandemic shutdowns can make some grease interceptors more hazardous to your health. Let’s find out why by taking a closer look at what happens in separators with little or no input flows.

Food waste contains sulfur. Naturally occurring bacteria eats the food and converts the sulfur into sulfite or sulfide constituents. In a grease separator with no water flow and a grease mat floating on the surface, the predominant bacteria are anaerobic.

Grease components trapped in an inactive separator are also being eaten by bacteria or broken down by hydrolysis into fatty acids. The longer the digestion phase (days), the shorter the fatty acid chain lengths. Eventually, these fatty acids are less than six carbons long. At that point, they are no longer miscible in water, which is a chemist’s way of saying the fatty acids are soluble and mix throughout the water. The water is more acidic.

Bullet Points:

- Anaerobic bacteria have eaten food waste

- Bacteria have converted the sulfur compounds in the food waste into sulfites and sulfides

- The grease mat has been gradually eaten by bacteria or decomposed by hydrolysis into short-chain fatty acids.

- Short-chain fatty acids are water-soluble and thus mix in the water instead of floating above in a grease mat

- The water in the grease separator is now acidic

There’s Danger Behind the Door (Grease Separator Cover)

Sulfite does not exist in acidic conditions below 6.0 pH, with all sulfites converting to sulfide in the form of Hydrogen Sulfide (H2S). Yes, we are speaking of the terrible rotten-egg-smelling hydrogen sulfide compound. Hydrogen sulfide is an Extreme Molecule. It is highly corrosive, and it is hazardous. Mammals are programmed to sniff hydrogen sulfide in concentrations as low as 0.13 parts per million. It’s all downhill from there:

- 0 to10 ppm irritates the eyes, nose, and throat. Bronchial constriction can occur with only 2 ppm in folks with asthma.

- 10 to 50 ppm leads to headaches, dizziness, nausea, vomiting, difficulty breathing.

- 50 ppm and greater concentrations are scary dangerous. Symptoms include shock, convulsions, coma, and death depending upon concentration and exposure time. 150-250 ppm concentrations trigger olfactory paralysis.

- Olfactory fatigue starts at 100 ppm. The nose does not smell H2S at concentrations above 100 ppm.

Why is this crucial now?

Because hydrogen sulfide is a gas, and it is soluble in water at low concentrations according to Henry’s Law. Raise the concentrations, and it wants to come out of the solution. Again, Henry’s Law applied to any gas present in water, be it air, methane, carbon dioxide, or hydrogen sulfide.

When flows pass through a grease separator, incoming water mixes with the water already in the separator and dilutes the residing water with its hydrogen sulfide concentration.

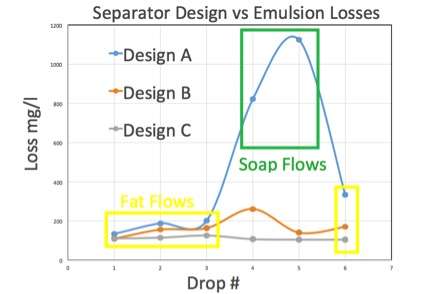

Let’s say a 1,000-gallon grease separator typically sees 200 gallons per day of flows. Every five (5) days, there is a 100% turnover (replacement) of the watery contents. Let’s also assume the displaced water has a 2 ppm concentration of hydrogen sulfide. With each day’s flow input of water, grease, and food constituents, this system’s profile should have a nearly steady 2 ppm hydrogen sulfide level in its watery contents.

Now, let’s stop sending water, food, and grease to this separator for several weeks. With no removal via incoming water flows, the hydrogen sulfide levels in the watery contents can reach 200 ppm or more.

Let’s say you’re taking a sludge and grease level assessment at a restaurant that has not been operating for an extended time. Or in a school cafeteria that has been closed for the summer. You put the tube down to the bottom and wham! Suddenly, you’re hit with a terrible rotten-egg smell. Then, you no longer smell it.

Please, jump back and leave the tube in the trap! Your life is in immediate danger!

Agitation by the assessment tube caused the concentrated, dissolved hydrogen sulfide gases in the watery contents to go from solution into bubbles releasing into the atmosphere. It is the agitated carbonated soda spewing phenomenon as described by Henry’s Law. Separators that have not had water inputs are dangerous.

What Else Happens When Separators Do Not Receive Flow Inputs?

- They can dry out and let sewer gas into a building

- Automatic units can experience component failures from lack of water harming the heater element.

- Concrete and ferrous metals corrode from exposure to concentrated levels of hydrogen sulfide and fatty acids.

As you ramp up in-person inspections, be especially careful in kitchens that are coming off a long period of inactivity. Your life depends on it.