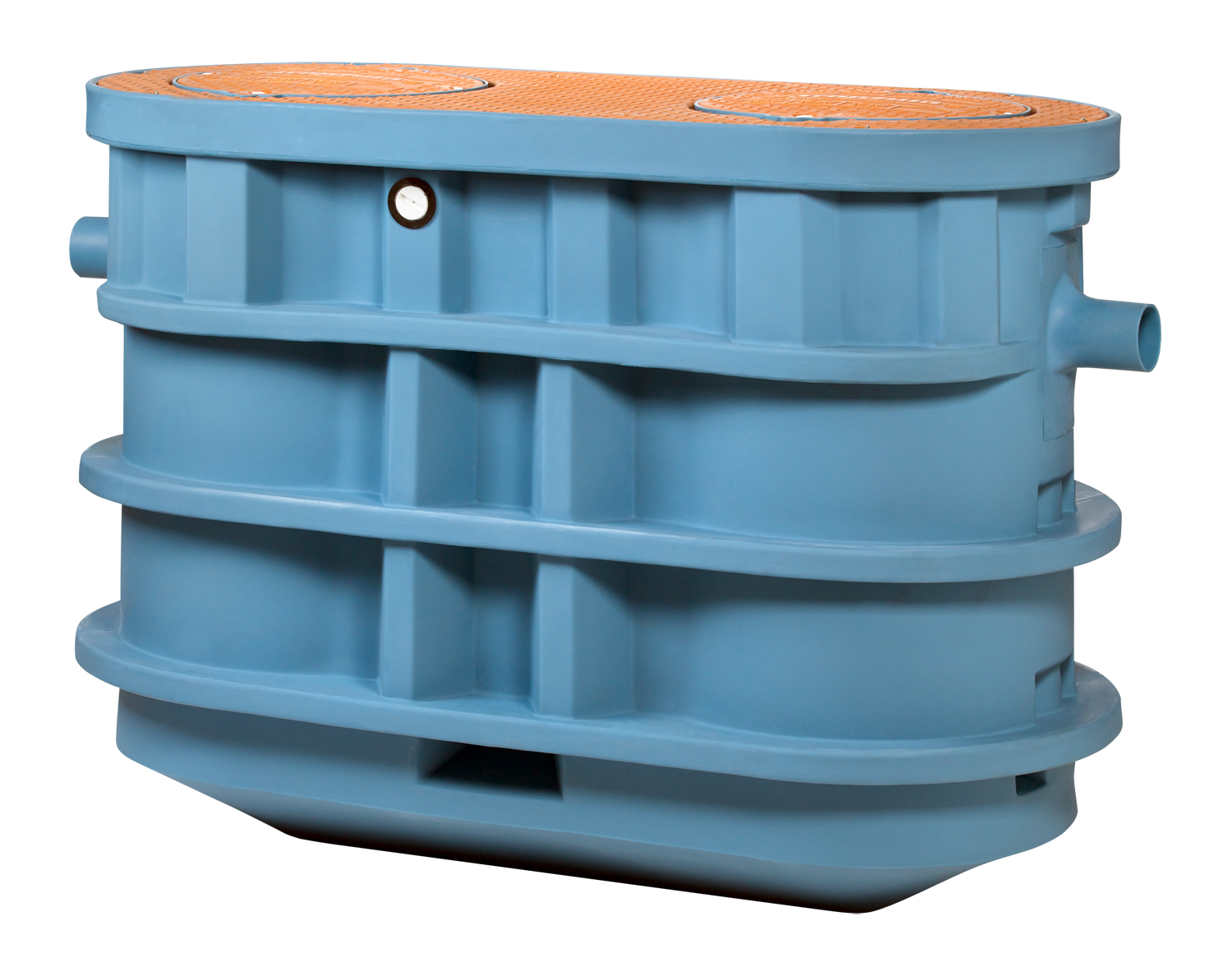

A better grease interceptor: More grease in less space

- Sep 1, 2015

To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.

To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.

The first is how many pounds of grease the TZ-1826 can hold. The second is how much a 1,000-gallon concrete trap weighs — a concrete trap that would hold a similar amount of grease, but would require heavy machinery to install and take up three times as much space as the TZ-1826.

How is that possible? That’s what happens when you apply a quarter century of grease interceptor innovation and oil-water separation expertise to a problem that a growing number of commercial food service establishments face: Lots of grease, but not much space for a high-capacity grease trap.

In 1884, Nathaniel Whiting patented the first grease interceptor design. These oversized, concrete boxes are still the default choice for many in the food-service industry.

In 1884, Nathaniel Whiting patented the first grease interceptor design. These oversized, concrete boxes are still the default choice for many in the food-service industry.